On Sunday, Oct. 8, 2023 the Minnesota Golden Gophers Men’s Hockey Team took to the ice at 3M at Mariucci Arena to play Bemidji State on a brand new ice surface. The refurbishment was the first major renovation to the arena since it was constructed in 1993. Brand new ice, rink boards, lighting – the works.

“This is probably the nicest barn I’ve ever set foot in compared to colleges across the country, professional teams and semi-professional teams.” explained Joshua simmons who works for Rink Systems of Albert Lea, Minn., a company that installs rink boards across the country.

The reconstructed ice sheet at 3M Arena at Mariucci will now be almost 89 feet in width as compared to the international-sized 100 feet it was previously. Eighty-five feet in width is the standard regulation width of a North American hockey rink. While the Gophers wanted a “hybrid” sized rink which is 92 feet in width, those dimensions didn’t materialize due to sightline restrictions. The official tape-to-tape measurement is now 88’ 9 ⅞ inches, just short of 89 feet. “Putting a hybrid-sized rink in an existing building rarely ever works,” said Simmons.

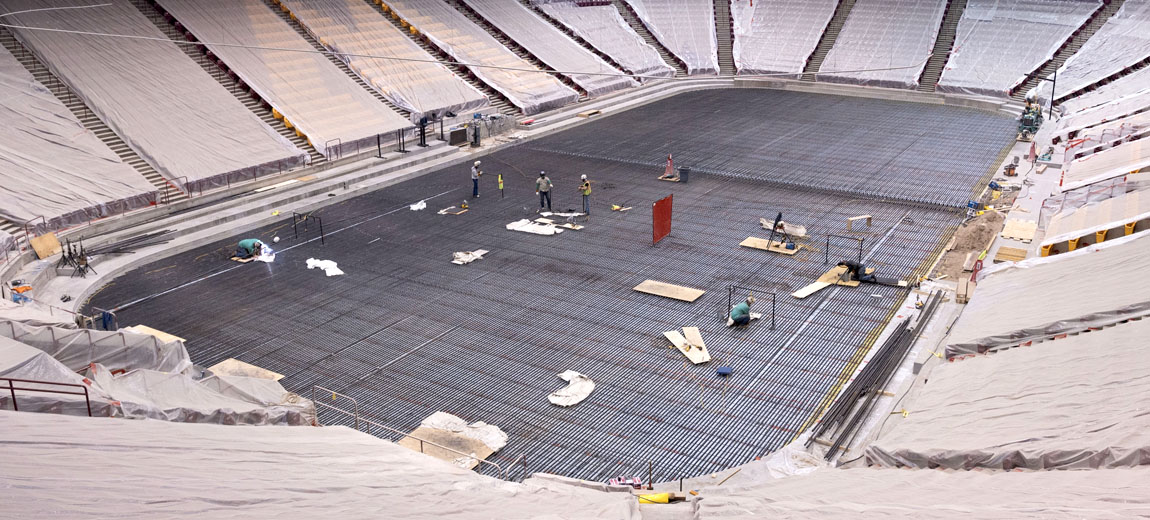

The union building trades were well represented on the renovation which began early last April by removing the concrete floor and the previous refrigeration unit that had been there since the rink was constructed. Mark Rodorigo, owner Commercial Refrigeration Systems located in Virginia, MN, whose company installed the refrigeration unit said, “This project here, bringing to you one of the finest ice rinks in the country, was built by all union labor.”

The union building trades were well represented on the renovation which began early last April by removing the concrete floor and the previous refrigeration unit that had been there since the rink was constructed. Mark Rodorigo, owner Commercial Refrigeration Systems located in Virginia, MN, whose company installed the refrigeration unit said, “This project here, bringing to you one of the finest ice rinks in the country, was built by all union labor.”

Operating engineers, iron workers, electricians, laborers, carpenters, insulators, pipefitters – all played a part in the job. The pipefitters were arguably the first stars as hockey rinks involve a substantial amount of refrigeration expertise. More than ten miles of pipe was put into the floor, all of it welded together on site. When the piping set up was tested in early July before concrete was poured over the pipes to form the floor, only seven leaks – just seven – were discovered out of 3,750 welds. Skilled labor demonstrates 99.8% proficiency – first time!

“People probably don’t realize our trade does install hockey rinks,” explained Chad Birk, Training Director of Local 539. “Inside those pipes is an antifreeze solution which is cooled down in a compressor in a mechanical room located near the ice and then pumped through the pipes. That’s how water put on top becomes ice.”

For Sam Rutledge, a Local 539 member, it was his third stadium job during his career as a pipefitter. He had two years of schooling before he joined the pipefitters apprentice program but found the experience very worthwhile. “Most everything you do on a job site you learn more about in the pipefitters’ school. It’s very practical that way,” he said.

Rutledge worked on both Target Field and US Bank Stadium projects. Unlike those stadiums which were “from the ground up” construction, the Mariuccui job was different because it’s a pre-existing structure. It was still a good experience though. He added, “Overall the crew gets along really well. Had a fair amount of fun throughout the day… at least as much fun as you can have.”

###